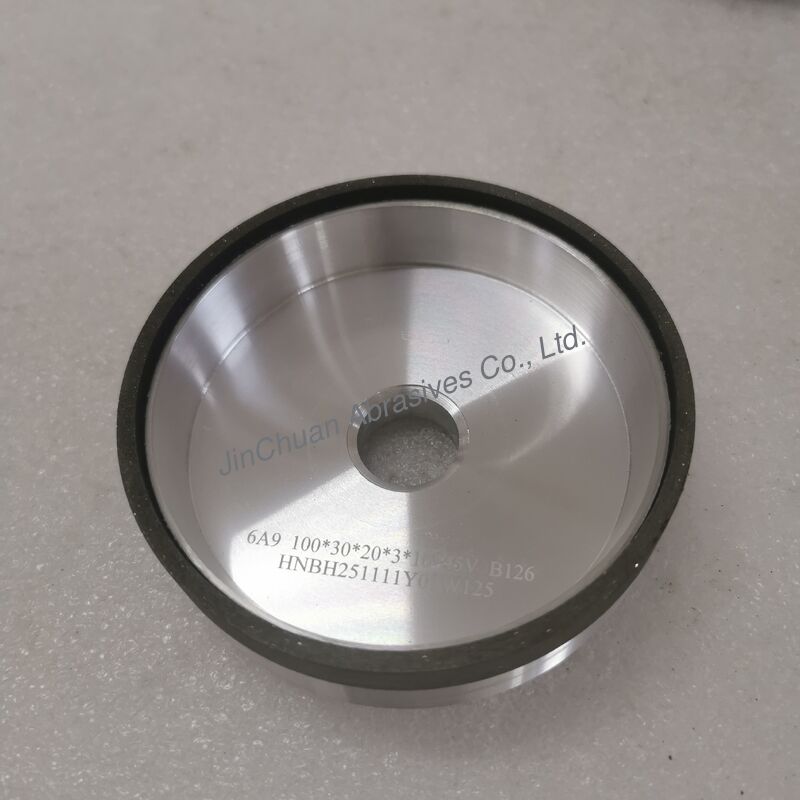

6A9 Résine de liaison CBN meuleuse 100*30T*20*3*10mm meuleuse à l'humidité B126

-

Mettre en évidence

Résine de liaison CBN meuleuse

,Roue en résine de broyage humide 100 mm

,B126 épaisseur de la roue CBN 30T

-

Diamètre100mm

-

Épaisseur30 mm

-

Trou intérieur20mm

-

Largeur de l'abrasif3mm

-

Hauteur abrasive10mm

-

GrincerB126

-

LierRésine

-

PrécisionHaut

-

Quelqu' un de base.Aluminium

-

Code Hs6804221000

-

EmballerBoîte en carton

-

Lieu d'origineChine

-

Nom de marqueJC

-

CertificationISO

-

Numéro de modèle6A9

-

Quantité de commande min2 pièces

-

PrixNégociable

-

Détails d'emballageune en carton

-

Délai de livraison7-10 jours

-

Conditions de paiementTT, Western Union, Paypal

-

Capacité d'approvisionnement10000/mois

6A9 Résine de liaison CBN meuleuse 100*30T*20*3*10mm meuleuse à l'humidité B126

Description du produit :

Les meules CBN à liant résine sont des outils de meulage fabriqués avec du nitrure de bore cubique (CBN) comme matériau abrasif et un liant résine. Elles sont spécialement conçues pour l'usinage de précision des métaux ferreux et des matériaux à haute dureté (tels que l'acier trempé, l'acier allié et l'acier résistant à la chaleur), couvrant des domaines tels que les pièces automobiles, les roulements, les moules et l'aérospatiale. Leur efficacité de traitement et la qualité de surface sont nettement supérieures à celles des meules traditionnelles, et elles sont compatibles avec les machines de meulage CNC à grande vitesse pour la production automatisée.

La structure de ces meules comprend une couche de travail (contenant l'abrasif), une couche de transition et une base. Elles sont classées en quatre types en fonction du liant : galvanisées, frittées, résine et céramique. Les types galvanisés conviennent au traitement de petits lots de formes complexes, les types résine sont utilisés pour le traitement des outils et du verre, et les types céramique, en raison de leur capacité à être retaillés et de leur résistance aux hautes températures, sont devenus la norme pour l'usinage à grande vitesse et de haute précision. Les meules CBN ont une dureté seconde seulement à celle du diamant, une résistance à la chaleur de 1250-1350 °C et une forte conductivité thermique, ce qui réduit la déformation thermique de la pièce. Leur inertie chimique les empêche de réagir facilement lors du traitement des métaux ferreux, mais les liquides de refroidissement alcalins doivent être évités.

Avec un code SH de 6804221000, nos meules d'affûtage CBN répondent aux normes internationales de qualité et de performance. Ces meules sont conçues pour fournir des solutions d'affûtage efficaces, réduisant les temps d'arrêt et augmentant la productivité dans les ateliers de menuiserie et les environnements industriels. Choisissez nos meules d'affûtage CBN pour les tourneurs sur bois et les machines d'affûtage de lames industrielles afin de bénéficier d'une précision et d'une efficacité d'affûtage optimales. Améliorez votre processus d'affûtage avec nos meules de haute qualité et obtenez des résultats supérieurs à chaque utilisation.

Paramètres techniques :

| Abrasif | CBN |

| Diamètre | 100 mm |

| Épaisseur | 30 mm |

| Trou intérieur | 20 mm |

| Largeur abrasive | 3 mm |

| Hauteur abrasive | 10 mm |

| Corps de base | Liant résine |

| Profil | Meulage de haute qualité |

| Granulométrie | B126 |

| Pays d'origine | Chine |

| Emballage | Emballage en carton exporté standard |

| Code SH | 6804221000 |

Applications :

De plus en plus de personnes choisissent les meules CBN, principalement en raison de leurs avantages tels que la résistance aux hautes températures, la forte inertie chimique, la grande durabilité et la précision et l'efficacité de traitement exceptionnelles, qui répondent aux exigences du meulage fin. Elles offrent un excellent rapport coût-efficacité et un bon rapport qualité-prix ; bien que le prix unitaire des meules CBN puisse être supérieur à celui des meules ordinaires, leur longue durée de vie et leurs faibles caractéristiques d'usure se traduisent par des coûts globaux inférieurs.

Les meules diamantées à liant résine sont principalement utilisées pour le meulage et la coupe de matériaux à haute dureté et difficiles à usiner. Les applications typiques incluent l'affûtage des outils en carbure, l'usinage de précision des céramiques techniques, du verre optique, des céramiques électroniques, des matériaux magnétiques, des pierres précieuses, ainsi que la coupe et l'amincissement des plaquettes de semi-conducteurs. En raison de leur haute résistance, de leurs excellentes propriétés d'auto-affûtage et de leur grande précision de traitement, elles sont largement utilisées dans la fabrication de précision.

Ces meules d'affûtage sont idéales pour une utilisation dans des industries telles que la métallurgie, le travail du bois, l'automobile, etc. Elles sont parfaites pour affûter une variété d'outils, notamment les forets, les couteaux, les ciseaux et autres outils de coupe. Avec une quantité minimale de commande de 1 et des détails d'emballage dans un carton, les meules d'affûtage JC CBN sont faciles à commander et à stocker. Le délai de livraison de 2 jours ouvrables vous garantit de recevoir votre produit rapidement, ce qui vous permet de vous mettre au travail rapidement.

Notre entreprise

Zhengzhou Jinchuan abrasive abrasive co., LTD. s'engage à fournir les produits en diamant et en nitrure de bore cubique les plus avancés. Nous avons des ingénieurs et des experts techniques expérimentés, des connaissances industrielles professionnelles et des services techniques pour aider les clients à trouver les meilleures solutions. Si vous avez des exigences de traitement spécifiques, veuillez nous contacter directement. Nous pouvons fournir le modèle de produit Hybrit le plus approprié et des recommandations de paramètres de traitement.

![]()

![]()